Understanding Prefabricated Homes: Affordable and Efficient Housing Options

Prefabricated homes are residential units manufactured in controlled facilities and assembled on-site. This approach integrates standardized components, quality control, and streamlined logistics to reduce on-site labor and construction time. The article explains how prefab housing functions and key considerations.

Prefabricated homes represent a growing segment of the housing market, offering an alternative path to homeownership that emphasizes efficiency, quality control, and cost predictability. Unlike traditional site-built homes, prefabricated structures are manufactured in controlled factory environments before being transported and assembled at their final locations. This construction method has evolved significantly over the decades, moving beyond basic designs to include sophisticated architectural styles that rival conventional homes in both aesthetics and functionality.

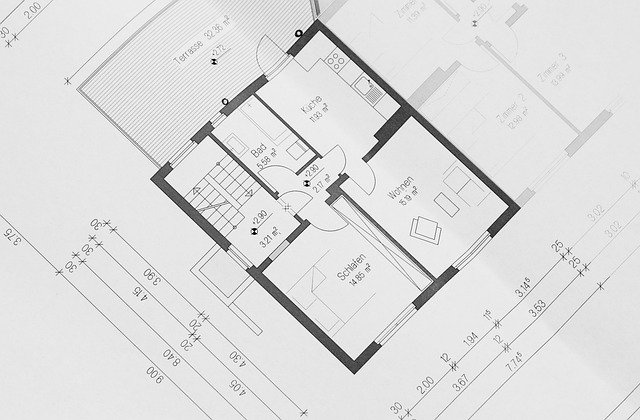

What are prefabricated homes and how do they work?

Prefabricated homes are residential structures where major components are manufactured off-site in a factory setting. The construction process involves building sections or modules in a controlled environment, which are then transported to the home site for assembly. This method differs fundamentally from traditional construction, where materials are delivered to a site and assembled from the ground up. The prefabrication process typically includes completing electrical systems, plumbing, insulation, and interior finishes before transport. Once the modules arrive at the destination, they are placed on a prepared foundation and connected together. The entire assembly process can take just days or weeks, compared to months for traditional builds. Quality control is enhanced because construction occurs indoors, protected from weather delays and material damage. Workers specialize in specific tasks within the factory, leading to consistent craftsmanship across all units produced.

How do efficient prefabricated homes compare to traditional construction?

Prefabricated homes offer several advantages over traditional construction methods. The factory environment allows for precise material measurements, reducing waste significantly compared to on-site building where excess materials are common. Construction timelines are dramatically shorter, with some homes ready for occupancy within three to four months from order to completion. Weather delays, which frequently push back traditional construction schedules, have minimal impact on prefabricated production. Energy efficiency is often superior in prefab homes due to tighter construction tolerances achieved in factory settings, resulting in better insulation and reduced air leakage. However, traditional construction offers greater customization flexibility, as changes can be made throughout the building process. Site-built homes also avoid transportation limitations that restrict the size and design of prefabricated modules. Financing can sometimes be more straightforward for traditional homes, as some lenders are more familiar with conventional construction loans. The resale value comparison varies by market, with prefabricated homes in some areas appreciating similarly to traditional homes, while in others they may face stigma affecting long-term value.

What types of prefabricated home designs are available?

The prefabricated housing market encompasses diverse design options to suit various preferences and needs. Modular homes consist of multiple sections built separately and joined on-site, offering flexibility in size and layout. These can range from compact single-story designs to expansive multi-level residences. Panelized homes involve wall panels, floor systems, and roof trusses manufactured in factories and assembled on-site, providing a middle ground between fully modular and traditional construction. Manufactured homes, built entirely in factories and transported as complete units, typically offer the most affordable entry point into homeownership. Contemporary prefab designs now include modern architectural styles with clean lines, open floor plans, and sustainable features like solar panel integration and rainwater collection systems. Tiny homes, typically under 400 square feet, represent a minimalist approach within the prefab category. Custom prefabricated homes allow buyers to work with manufacturers to create unique designs while maintaining the efficiency benefits of factory construction. Many manufacturers now offer design software that lets potential buyers visualize and modify floor plans before production begins.

Understanding prefabricated home costs and providers

The cost of prefabricated homes varies widely based on size, design complexity, materials, and location. Understanding the financial landscape helps buyers set realistic expectations and budget appropriately. Several established manufacturers operate across the United States, each offering different price points and features.

| Provider | Home Type | Cost Estimation |

|---|---|---|

| Clayton Homes | Manufactured/Modular | $50,000 - $150,000 |

| Blu Homes | Modern Modular | $200,000 - $500,000 |

| Champion Home Builders | Manufactured | $40,000 - $120,000 |

| Method Homes | Contemporary Modular | $150,000 - $400,000 |

| Cavco Industries | Manufactured/Park Models | $35,000 - $100,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Beyond the base home cost, buyers should budget for land preparation, foundation work, utility connections, transportation, and assembly. Site preparation can range from $5,000 to $30,000 depending on terrain and existing infrastructure. Foundation costs typically fall between $10,000 and $25,000. Transportation expenses vary based on distance from the factory, with costs increasing significantly for remote locations. Some manufacturers include delivery and setup in their pricing, while others charge separately. Financing options have expanded as prefabricated homes gain acceptance, with many conventional mortgage lenders now offering loans comparable to traditional home financing. However, manufactured homes on leased land may require specialized lending products with different terms.

How do zoning laws and building codes affect prefab installation and global uses?

Navigating regulatory requirements is essential for successful prefabricated home installation. Zoning laws determine where different types of homes can be placed, with some municipalities restricting manufactured homes to specific zones or requiring them to meet aesthetic standards matching surrounding properties. Local building codes dictate construction standards, and while prefabricated homes must meet national codes, some jurisdictions impose additional requirements. Modular homes typically face fewer restrictions than manufactured homes because they are built to the same codes as site-built houses. Prospective buyers should verify local regulations before purchasing, as some areas prohibit certain prefab types entirely. Foundation requirements vary by region, with considerations for frost lines, seismic activity, and flood zones affecting installation costs and methods. Permits are necessary for placement and utility connections, with approval processes taking weeks to months depending on local government efficiency. Internationally, prefabricated housing has gained traction in countries facing housing shortages or seeking sustainable building methods. European nations have embraced prefab construction for its energy efficiency, while developing countries utilize it for rapid housing deployment in growing urban areas. Building standards differ globally, so manufacturers must adapt designs to meet regional requirements when exporting prefabricated homes.

Prefabricated homes continue to evolve as manufacturing techniques improve and consumer acceptance grows. They offer a viable path to homeownership for those prioritizing efficiency, cost predictability, and quality construction. While not suitable for every situation or preference, prefabricated housing addresses many challenges facing today’s housing market, providing options that balance affordability with modern living standards. Prospective buyers who research thoroughly, understand local regulations, and work with reputable manufacturers can find prefabricated homes that meet their needs and provide long-term value.